How to Cut Hydraulic Hose

Hose and Fitting Supply provides industry-leading hydraulic hoses, known for their durable rubber construction and high-tensile steel wire reinforcement. These hoses are built to withstand extreme pressures and harsh conditions in both oil and water-based systems. To create a custom or replacement hose assembly, proper cutting of bulk hydraulic hose is the critical first step before attaching your braided hose crimp fittings. A clean, square cut is essential for achieving a secure, leak-free connection and maintaining the integrity of the SAE-rated hose.

Selecting the Right Tools for a Clean Cut

Using the correct tool is paramount to preventing damage to the hose’s internal wire braid and ensuring a perfect seal. Avoid using tools like saws or grinders, as they can generate heat, leave burrs, or unravel the reinforcement layer, compromising the hose’s strength. For a professional result, we recommend a dedicated hydraulic hose cutter. These tools are designed to shear the hose cleanly with a scissor-like or ratcheting action, producing a perfectly square end without deforming the tubing or damaging the steel wires. This precision is what allows our high-quality hoses to form a perfect seal with Weatherhead, Aeroquip, and Parker-compatible fittings.

A Step-by-Step Guide to Cutting Hydraulic Hose

-

Measure and Mark: Precisely measure the required length for your application. Use a white or silver marker to create a clear, straight line around the circumference of the hose. For best accuracy, you can use a hose-cutting guide or a simple piece of paper wrapped tightly around the hose as a straight edge.

-

Secure the Hose: Place the hose securely in a vise. To avoid crushing the hose and damaging its structure, use vise pads or dedicate a small section of scrap hose as a protective sleeve where the jaws make contact.

-

Position the Cutter: Open your hydraulic hose cutter and position the blade directly on your marked line. Ensure the cutter is held perfectly perpendicular to the hose to guarantee a 90-degree square cut.

-

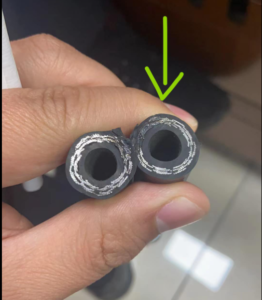

Execute the Cut: Apply steady, even pressure to the cutter handles. For ratcheting models, continue cycling the handles until the blade cleanly shears through the hose. The result should be a smooth, square end with no frayed wires or rubber debris.

By following these steps with the right equipment, you can confidently prepare your bulk hydraulic hose for the crimping process. This ensures your final assembly maintains the full pressure rating and reliability that our products are known for, making it a dependable component in your hydraulic equipment. Explore our full range of bulk hoses and crimp fittings to build your custom solution today.