Introduction to EPDM rubber

EPDM rubber, as a great material, appears in every corner of our daily life and industry. Today, let us take a brief look at it.

1: What is EPDM rubber? EPDM rubber is made from the copolymerization of ethylene and propylene in solution. It is a saturated polymer.

2: What are the characteristics? EPDM rubber has excellent weather resistance, aging resistance, chemical resistance and electrical insulation. It is flexible and impact-resistant, and its most important features are:

1. Good filler EPDM rubber has a low density of 0.87, which means that fillers can be added to reduce costs to make up for the high price of EPDM rubber. Fillers do not seriously affect mechanical properties.

2. Anti-aging EPDM rubber has excellent weather resistance, ozone resistance, heat resistance, acid and alkali resistance. It can work at 120℃ for a long time and 150-200℃ for a short time. Adding certain antioxidants can increase the working temperature. With an ozone concentration of 50pphm and a stretch of 30%, EPDM rubber can be used for more than 150 hours without cracking.

3. Corrosion resistance: EPDM rubber lacks polarity and has low unsaturation. Therefore it is resistant to polar chemicals such as alcohols, acids, bases, oxidants, refrigerants, ketones and fats.

4. Steam resistance EPDM rubber has excellent steam resistance and heat resistance. There is no change in appearance after 100 hours of superheated steam testing at 230°C. Other rubbers such as nitrile rubber will deteriorate in appearance under the same conditions.

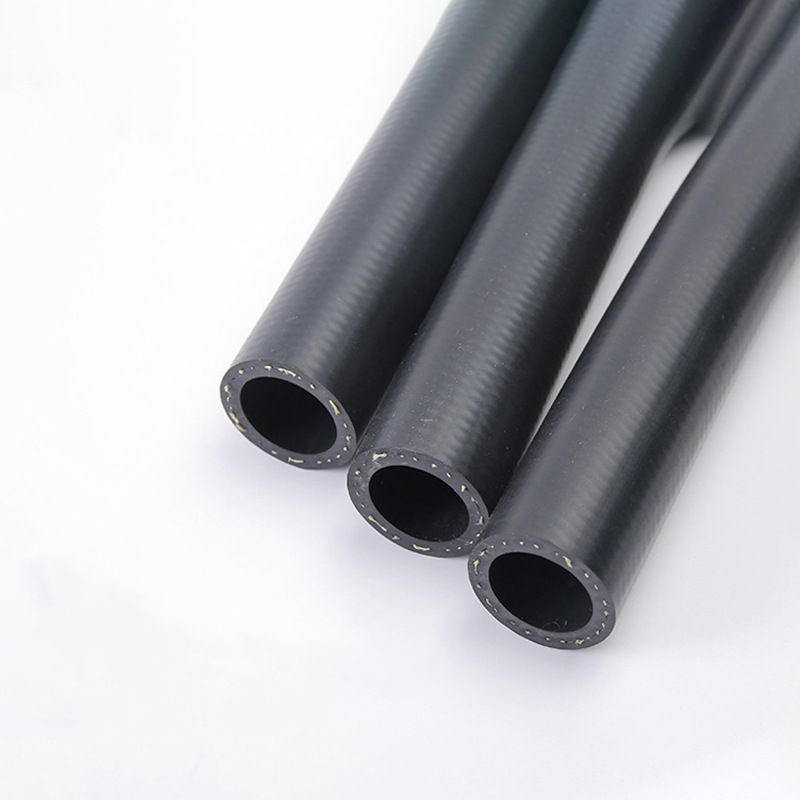

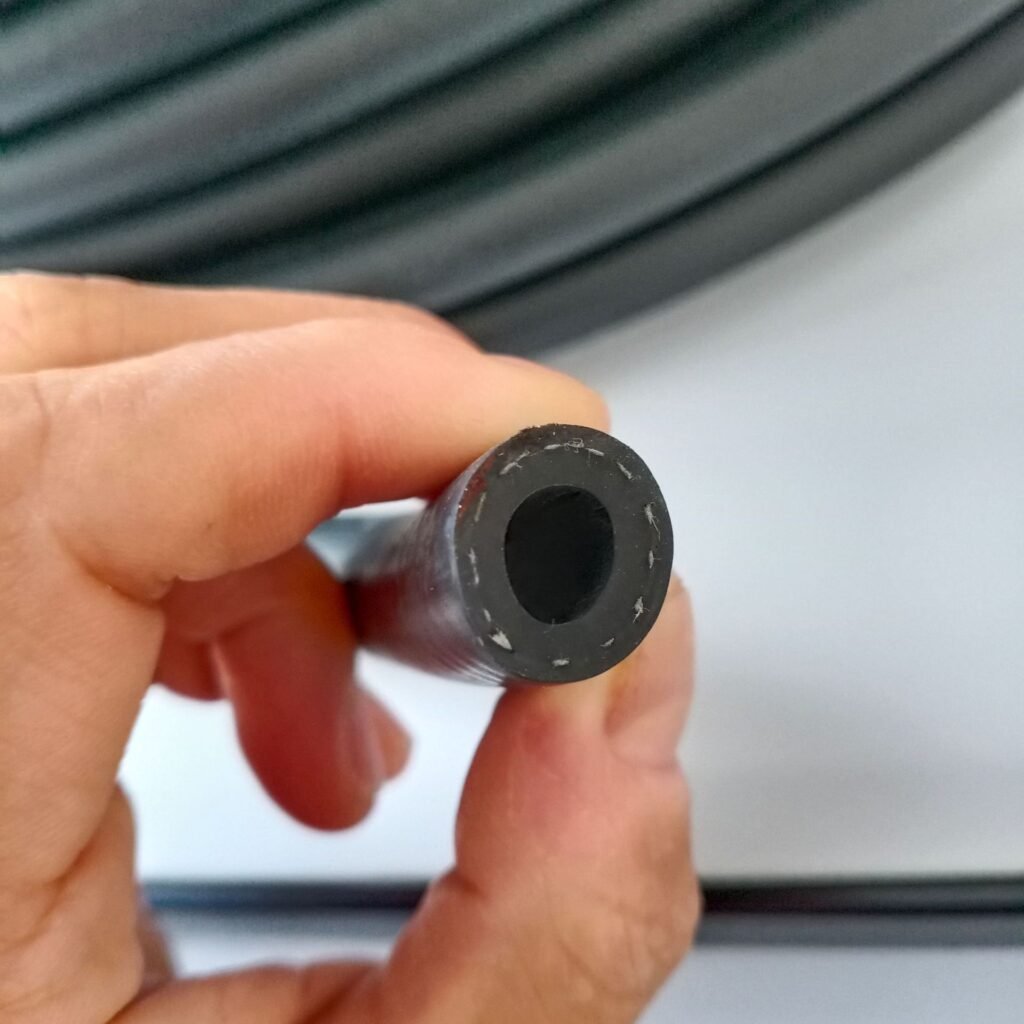

5. What are the applications? Due to its excellent performance, it is widely used in wires, gaskets, seals, waterproof materials, protective sleeves, hoses and rubber sheets in the fields of automobiles, shrinkage, military industry, aerospace and other fields.