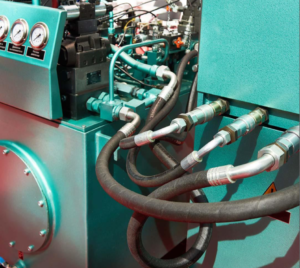

Powering Motion: Hydraulic Hoses

At the heart of every powerful hydraulic system lies a critical component: the hydraulic rubber hose. This flexible conduit is the vital lifeline, engineered to transmit high-pressure fluid power to actuators, motors, and cylinders, enabling the immense force that drives modern machinery.

Robust Construction for Demanding Applications

A hydraulic hose is far more than a simple tube. It is a marvel of engineering, built with a multi-layer structure designed for performance and durability:

-

Inner Tube: A seamless, oil-resistant synthetic rubber layer that ensures smooth fluid flow and resists degradation from hydraulic oils and temperatures.

-

Reinforcement Layer: The core of its strength, this layer consists of high-tensile textile braids or spiraled steel wire, engineered to contain extreme internal pressure and handle impulse cycles.

-

Outer Cover: A tough, abrasion-resistant rubber shell that protects the hose from external damage, weather, ozone, and chemicals, ensuring long service life in harsh environments.

Where Dependability is Non-Negotiable

The reliability of hydraulic hoses is paramount across countless industries. They are the unsung heroes in:

-

Construction & Mining: Excavators, bulldozers, and drills rely on them for powerful, precise movements under extreme stress.

-

Agriculture: Tractors and combines use them for steering, lifting, and implement control.

-

Manufacturing: Injection molding machines and metal presses depend on their consistent performance.

-

Logistics & Transportation: From forklifts to garbage trucks, they enable essential lifting and compacting functions.

Selecting the Right Hose for Your System

Choosing the correct hydraulic hose is critical for safety and efficiency. Key specifications to consider include:

-

Inner Diameter: Ensures proper fluid flow to maintain system efficiency and prevent overheating.

-

Working Pressure: The maximum continuous pressure the hose is rated to handle, which must exceed your system’s maximum operating pressure.

-

Temperature Range: The span of ambient and fluid temperatures the hose can withstand without compromising its integrity.

-

Compatibility: Confirming the hose materials are compatible with the specific hydraulic fluid used.

By understanding their construction, applications, and selection criteria, you can ensure your hydraulic systems operate with the power, precision, and—most importantly—the safety they were designed for.